DLR is More Than Optimizing Capacity; How Can Utilities Ensure Safety and Reliability?

Dynamic line rating (DLR) enables utilities to unlock up to 40% additional capacity from existing infrastructure, allowing grid operators to rapidly increase energy throughput. This capability is crucial in today’s energy landscape, where the proportion of renewable energy sources is quickly expanding, and the existing aging infrastructure cannot support this growing demand. Operating power lines closer to their true limits maximizes their power-carrying capacity—a vital step in transitioning from conservative static line ratings (SLR) to more dynamic, efficient capacity management. However, it's essential that this optimization does not compromise the grid's reliability. Safely enhancing capacity ensures the reliability of the grid even as it adapts to the evolving demands of modern energy consumption.

Operating Above Safe Thermal Limits Does More Than Damage the Conductor

DLR enables adjustments in power line capacity by monitoring conditions such as temperature, wind speed, and solar radiation. The capacity, or ampacity, of a conductor is not just about handling power flow—it also involves maintaining the line within safe thermal limits to prevent damage and ensure longevity. Operating above these limits can cause conductors to sag, risking electrical faults, and increasing maintenance needs, ultimately leading to higher costs and potential service disruptions. Thermal limits are defined by the maximum temperature a line can withstand before the integrity of the conductor is compromised. Globally, these limits vary but are fundamentally designed to prevent the conductor from annealing, a process that weakens the material. When the conductor’s temperature exceeds its maximum allowable temperature, the risk of long-term damage increases. The implications of ignoring these limits are significant. A conductor heated beyond its thermal threshold can expand and sag, posing serious safety risks, including increased chances of sparking wildfires or creating outages by coming into contact with trees or other objects. In a study conducted by Laki Power, the performance of a 200km power line was analyzed over an 8-month period. It was found that for 3.3% of the time, DLR was lower than the SLR, causing the conductor temperature to exceed its thermal rating. This corresponds to 191 hours during which the conductor could have operated above its maximum allowable temperature of 80°C, despite being within the SLR limit. According to the datasheet, the emergency operation temperature for the ACSR “Condor” conductor is 90°C and should be limited to 10 hours or less per year. Assuming the power line was operating at SLR, calculations based on historical weather data showed that during this 8-month period, the power line would have exceeded its emergency rating for 43 hours. [caption id="attachment_219912" align="aligncenter" width="403"]

The number of hours where the DLR was below SLR in specific months. Source: Laki Power DLR Feasibility Study[/caption] This study illustrates that the DLR’s value extends beyond merely increasing the transmission capacity, it can also detect when the DLR falls below the SLR, which is crucial for preventing potential damage to the infrastructure and enhancing overall system reliability. By closely monitoring and adjusting to actual line conditions, DLR helps maintain the line within safe thermal limits, thus reducing the risk of overloading, which can lead to costly repairs and downtime disrupting service to thousands of customers.

Implications of Inaccurate Wind Weather Data in DLR

The accuracy of weather data is crucial in DLR, since environmental factors heavily influence the ampacity of power lines, and inaccuracies in wind speed data can lead to underutilization of the line’s capacity and lost revenues. In the previously referenced study, Laki Power also saw that wind conditions have the biggest impact on the ampacity ratings, and increasing the wind speed from 0.6 m/s to 1.6 m/s at a 45° wind-to-line angle can increase the ampacity by 43% and the same wind speed but at 90° wind-to-line angle can increase the ampacity by 54%. This highlights the importance of having a DLR system like Laki Power’s LKX-MULTI, which measures real-time weather parameters (wind speed and wind-to-line angle) at the exact power line location, therefore enabling operators to transmit more power safely through the line. Furthermore, the referenced Laki Power study concluded that the application of DLR would have an average capacity increase of 39.9% with the potential to boost revenues up to USD 49.7 million for the 8-month period or USD 75 million annually. [caption id="attachment_219909" align="aligncenter" width="453"]

A comparison of SLR vs. DLR over an 8-month period. The average capacity increase for this period was 39.9%. Source: Laki Power DLR Feasibility Study[/caption]

Accurate Weather Intelligence Increases the Grid's Safety and Reliability

The conductor’s temperature is affected by various external conditions, one of them being weather, wind in particular. A conductor is subject to two heat sources and two cooling sources. The heat sources are heating from the sun and heating from the current on the line and the cooling sources a convective cooling from the wind and radiative cooling which is driven by the ambient temperature. If the ambient temperature is colder than the conductor, you will have a cooling effect. The interplay between these heat sources and cooling methods determines the conductor's temperature and, by extension, its operational capacity and safety clearances. [caption id="attachment_219908" align="aligncenter" width="640"]

How heating and cooling affect the conductor. Source: CIGRE Guide for Thermal Ratings Calculations of Overhead Lines[/caption] Most grid operators use SLRs for the maximum ampacity which incorporates predefined conservative weather conditions. However, most of the time there is higher wind speed and lower ambient temperature than defined in the SLR, meaning there is a capability to transmit more power through the line. Therefore, by integrating accurate real-time weather intelligence such as wind speed and wind-to-line angle into their DLR systems, grid operators will optimize their capacity and preserve the infrastructure by preventing the possibility of conductor damage. In times of extreme weather conditions, this responsiveness is essential for maintaining system reliability and extending the life span of the infrastructure.

Harnessing Localized Weather Data to Improve DLR Forecasting

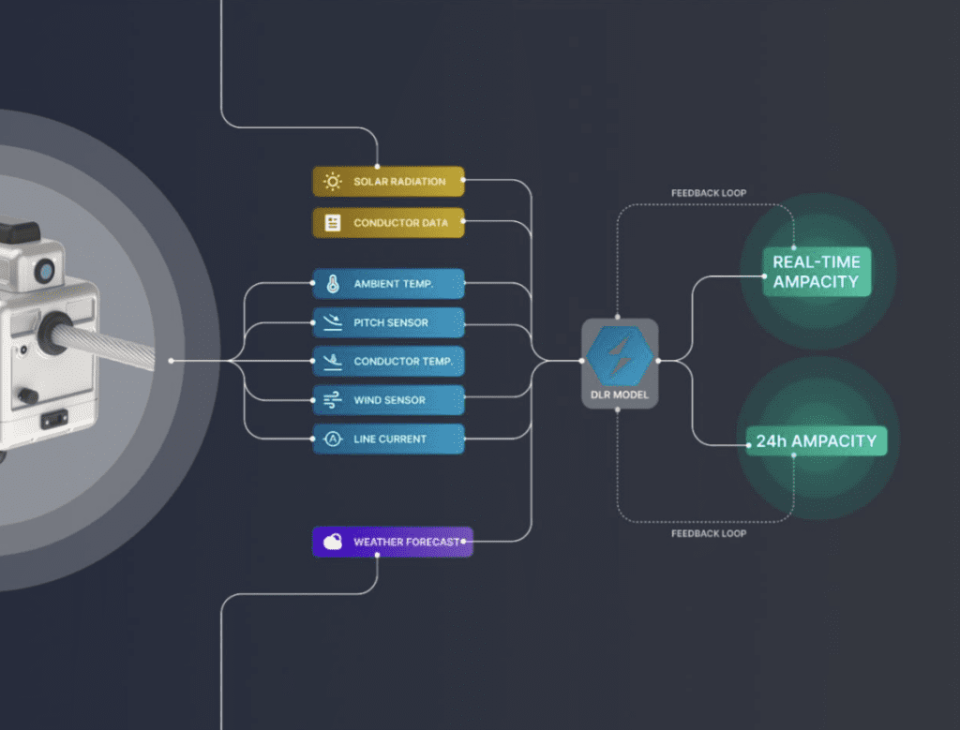

The micro-climate variations along transmission lines can be significant, especially in geographically diverse regions. Third-party weather data and weather stations located miles from the transmission line might miss these nuances, leading to a one-size-fits-all approach in weather assessments that could compromise the accuracy of DLR. Utilizing micro-climate wind data, as captured by devices like the LKX-MULTI, allows for a much more localized and precise adjustment to line ratings and forecasts. The LKX-MULTI’s DLR model utilizes third-party weather forecasts and localized weather data to continuously improve its real-time ampacity and 24-hour ampacity prediction forecast models. To validate and improve its predictions and overall DLR model, real-time wind measurements from the LKX-MULTI are compared to third-party forecasted wind measurements, and the difference is fed into the DLR model, creating a feedback loop for continuous improvement of the DLR predictions. [caption id="attachment_219911" align="aligncenter" width="640"]

Laki Power's dynamic line rating model. Source: Laki Power[/caption] This level of detail is crucial for tailoring operations to the specific conditions each segment of the grid faces, which in turn enhances safety and efficiency.

Grid Safety and Reliability Can Be Achieved with Localized and Accurate Weather Intelligence

By incorporating localized weather intelligence into their operational strategies, grid operators can significantly improve the safety and reliability of their DLR systems. This approach enables a dynamic response to changing weather conditions, reducing the risk of operating beyond safe thermal limits and improving overall grid management. While DLR offers the potential to maximize the throughput of existing transmission lines, its successful implementation hinges on rigorous adherence to safety protocols and the reliability of localized weather data. By investing in GETs and prioritizing accurate environmental information, utilities can ensure that their infrastructures not only meet today’s demand but are also prepared for tomorrow’s challenges. — Ósvaldur Knudsen is CEO at Reykjavík, Iceland-based Laki Power.

Yahoo Finance

Yahoo Finance