Is AR paving the way for the industrial metaverse?

Here's how the Mercedes-AMG Petronas F1 team and Hyundai Motor Company are using TeamViewer's AR for the industrial metaverse.

Since the metaverse for consumers is still being defined, perhaps the industrial metaverse will make its debut first.

The industrial metaverse aims to create holistic, real-time digital twins of entire factories – including various elements such as machines, robots, automated guided vehicles and workers – according to TeamViewer, a provider connectivity and workplace digitalisation solutions.

Oliver Steil, TeamViewer’s chief executive officer, shares that companies across various industries are leveraging augmented reality (AR) solutions as one of the ways to realise an industrial metaverse. These companies include car manufacturer Audi and Coca Cola Hellenic Bottling Company.

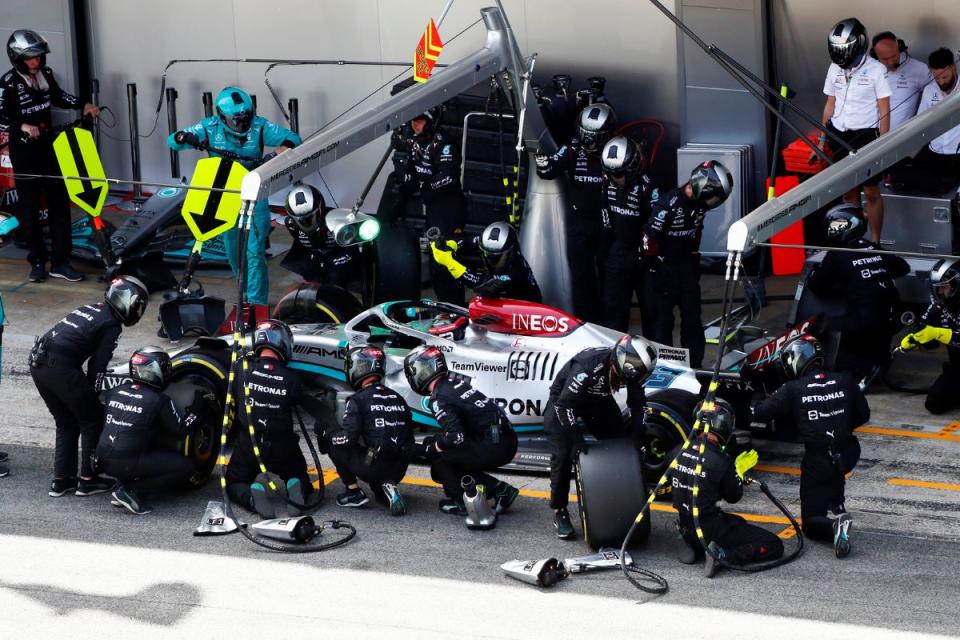

In the case of the Mercedes-AMG Petronas F1 team and Mercedes-EQ FE team, they are using TeamViewer’s solutions – including remote access and connectivity, AR glasses, and AI – to conduct crucial tasks.

With TeamViewer enabling them to monitor and connect to the laboratories remotely, technicians and engineers can run tests out of working hours and conduct multiple tests simultaneously.

TeamViewer is also being used on race days to provide an essential remote connection between the trackside crew and the engineers and data based in the Mercedes factory in the UK. Besides helping to improve trackside performance, this also supports the teams’ sustainability efforts as fewer team members and third parties are needed to travel with the teams to physically inspect and repair the cars on race weekends.

Supporting Hyundai Motor’s Meta-Factory

Photo: TeamViewer

Earlier this year, Hyundai Motor Company announced its Meta-Factory concept, which involves a digital twin of an actual factory supported by a metaverse platform.

The first Meta-Factory concept will be first applied to the Hyundai Motor Group Innovation Centre in Singapore (HMGICS). The facility serves as Hyundai Motor Group’s test bed and global open innovation hub, which aims to develop new electric vehicle business models, forge innovative mobility partnerships, produce mobility products and verify the group’s intelligent manufacturing platform to revolutionise the overall mobility value chain.

To realise the Meta-Factory concept, HMGICS will use TeamViewer’s AR platform – including mixed reality and AI capabilities – to support assembly, maintenance, quality management, logistics, client experience projects and workforce training.

The move will help improve productivity, accuracy, speed and safety of frontline production workers at the facility.

Additionally, HMGICS and TeamViewer will conduct joint research and development (R&D) activities in AR-powered smart factory operations, immersive digital experience for frontline workers and AI support for a future automotive factory.

“Developing an intelligent manufacturing platform is an important part of Hyundai’s strategy to lead the future mobility industry. We are continuously innovating the overall mobility value chain, which includes presenting a vision for a future mobility smart factory. We expect the partnership will further accelerate our transition to a smart factory and enhance its efficiency,” says Hong Bum Jung, CEO of HMGICS.

Sojung Lee, president for TeamViewer Asia Pacific, adds: “As digital transformation has accelerated on the shop floor, there is a growing need for AR solutions like TeamViewer Frontline that help by optimising manual work processes in industrial environments. Our collaboration with Hyundai Motor Company will further solidify our position as an enterprise software provider with specialised solutions for the manufacturing industry, and it will strengthen our role as a leading player in the industrial metaverse space.”

When asked about Asia Pacific’s appetite for the industrial metaverse, Steil says that while more needs to be done for the concept to become mainstream, adoption in the region is expected to be better than that in the European market. This is because companies here “have the mindset to digitalise and are open to using technology”.

He continues: “We’ve addressed the hardware challenges – such as noise cancellation, battery life, latency – and improved AR solutions' usability by working with software partners like SAP and Siemens. We are also working with telcos so that [industrial AR solutions] are offered as out-of-the-box, saving customers the hassle of looking for different vendors for different aspects of the industrial metaverse. All these efforts will help encourage adoption and enable the industrial metaverse to become mainstream in a few years’ time.”

See Also:

Click here to stay updated with the Latest Business & Investment News in Singapore

DBS partners The Sandbox to create metaverse platform DBS BetterWorld

Get in-depth insights from our expert contributors, and dive into financial and economic trends

Yahoo Finance

Yahoo Finance